Loading and unloading

Our patented technology enables the contactless loading and unloading of substrates from the carrier to the process tool and back. The ultrasonic suspension technology generates a supporting gas film (air or process gas) between the system and the substrate, which causes the substrate to hover on the gas film. This enables contactless gripping, alignment and centering of the substrate.

Advantages:- The surface is not damaged by contactless handling

- No particle deposition, no effect on cleanroom conditions

- Flatness of the substrate during the transfer process, leads to a low substrate tension

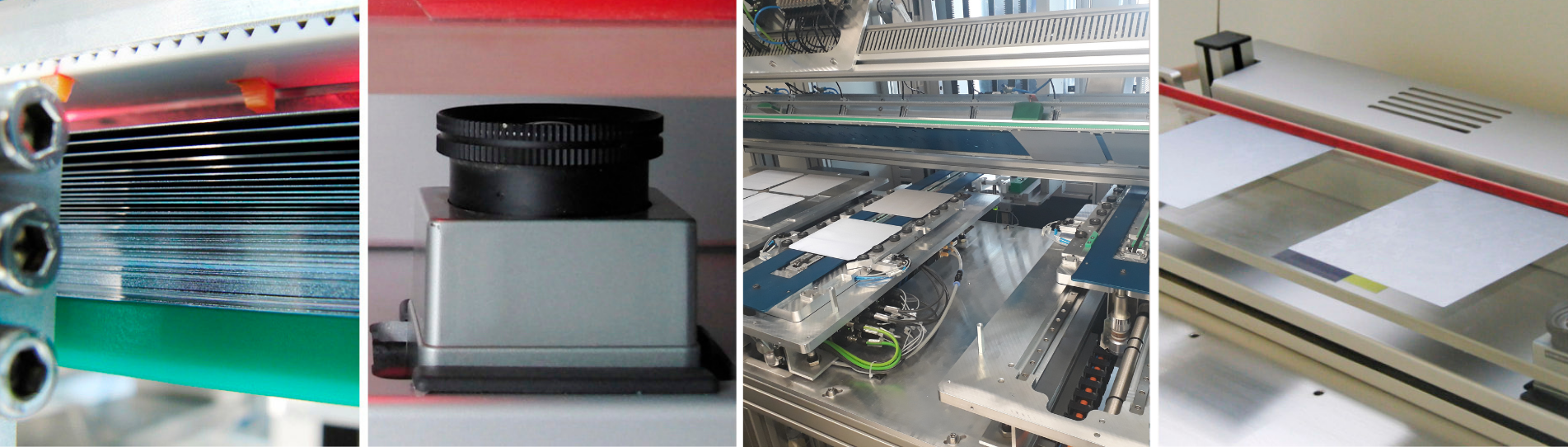

Conveying

Our patented technology allows the contactless transport of substrates on an assembly line. The ultrasonic suspension generates a supporting gas-film (air or process-gas) between the surface of the line and the substrate, which causes the substrate to hover on the gas film. The contactless conveyor system allows the friction free transport of substrates.

There is the possibility for double-sided inspection of the substrates:- Intersection of the transfer system with a gap that can be easily crossed by the substrate while the inspection is performed in this gap

- Insertion of a glass sonotrode as part of the conveyor table, inspection of the substrate through the glass with an optical aid

- No surface contact, no damages during the transport

- Modular design

- Low energy consumption

The non-contact gripping of substrates enables handling without surface contact. Our ultrasonic bearing technology generates a supporting gas film (air or process gas) that causes the substrate to float on the gas film. By combining ultrasound and vacuum, we enable gripping from above.

Advantages:- No surface contact, no damages during the transport

- Modular design

- Low energy consumption

Inspection

The contactless conveying of substrates enables a friction free inspection. The ultrasonic suspension generates a supporting gas-film (air or process-gas) between the surface of the line and the substrate, which causes the substrate to hover on or below the gas film.

It provides the possibility for double-sided inspection of the substrates:

- Intersection of the transfer system with a gap that can be easily crossed by the substrate while the inspection is performed in this gap

- Insertion of glass sonotrode as part of the conveyor table, inspection of the substrate through the glass with an optical aid

- No surface contact, no damages during the transport

- Modular design

- Low energy consumption

Sorting

Contactless placing and sorting of substrates. Due to the equilibrium of forces between low pressure, ultrasound and gravity, the substrates can be gripped from the top side without contact and transported on the conveyor system. As soon as the substrate is above the desired position, the low pressure is turned off and the repulsive force of the ultrasound causes the substrate to fall into the desired position.

The substrates can be sorted in different types of container systems, such as shelves and trays.

Products which can be combined:

- PV-Gripper

- Picker Module

- Linear-Transfer Module

- Inspection Module

- No surface contact, no damages during the transport

- Modular design

- Low energy consumption

Separating

When separating wafers, our patented ultrasonic suspension technology enables a contactless gripping process without touching the surfaces. The wafer will be taken friction-free from the stack or cassette and transferred to the transport system or process station without contact.

The main advantage besides the contactless gripping is a considerably higher cycle time than with conventional Pick & Place processes.

Advantages:- No surface contact, no damages during the transport

- Modular design

- Low energy consumption