Levi-Loader

CONTACTLESS PICK & PLACE OF SOLAR WAFERS

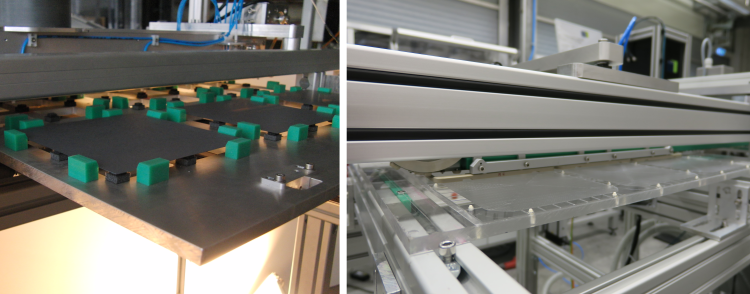

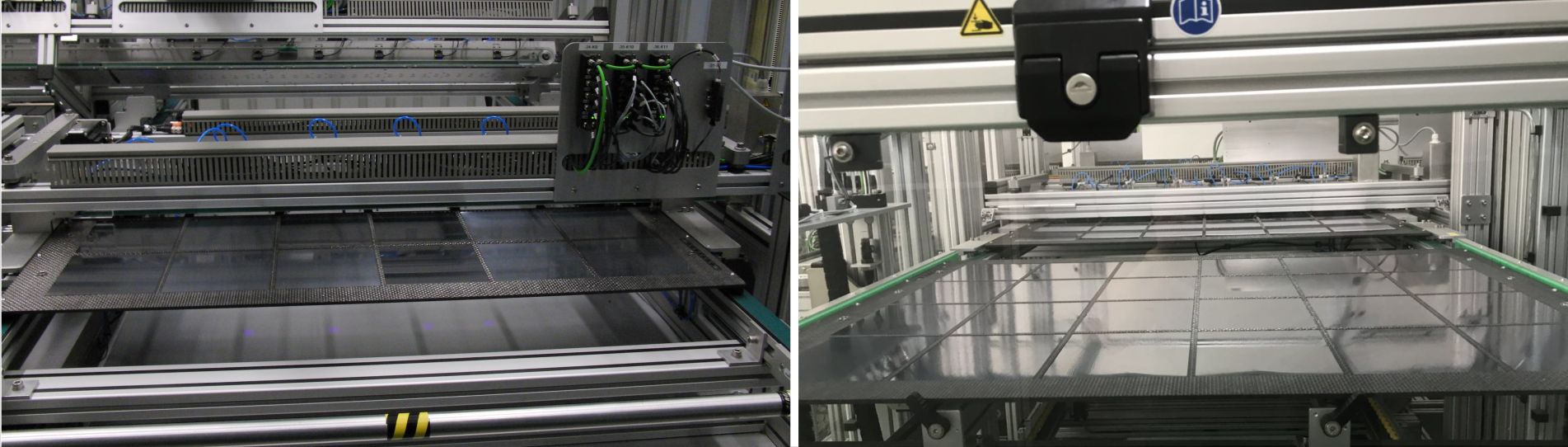

With the Levi-Loader, several solar wafers can be picked up and transported simultaneously without any contact. Precise positioning of wafers on the matrix tray by linear motors or belts with pins is possible as well.

No particle transfer and reduced breakage rate at high speeds

When gripping the wafers from above, a combination of vacuum and ultrasound is used. While vacuum provides an attracting effect on the wafers, the repulsive force of ultrasound keeps the distance between the Levi-Loader and its workpiece.

This eliminates the possibility of damage to the sensitive solar wafers in form of micro-scratches, micro-cracks or particle contamination. In addition to the resulting lower breakage rate, solar cell parameters such as efficiency and service life are significantly increased by avoiding contact and thus particle transfer.

The number of wafers being handled simultaneously is variable and individually adjustable which allows very high throughput rates to be achieved.

Features of the Levi-Loader:

-

Non-contact loading and unloading

-

Simultaneous handling of multiple solar wafers

-

very high throughputs feasible

-

No damage and no particle transfer

-

Precise positioning of wafers on the tray

-

Individually adaptable