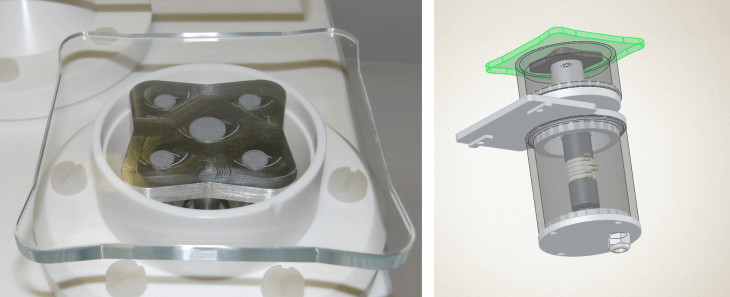

UltraLevi-Chuck

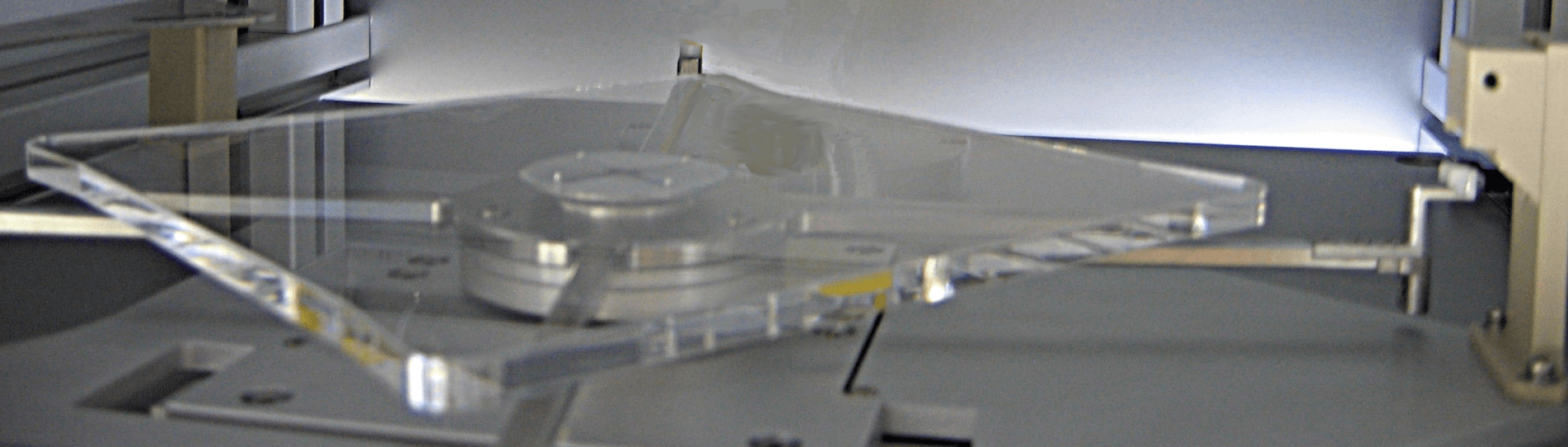

HIGH FLATNESS OF THE SUBSTRATE, ALSO FOR FLEXIBLE MATERIALS

The UltraLevi-Chuck holds the substrate or wafer in position without surface contact. Very thin and unstable wafers can be smoothed out additionally by the supplementary use of vacuum.

The UltraLevi-Chuck causes the substrate to float on a film of air. Unlike other non-contact chucks, ultrasonic bearing technology does not require the use of compressed air which eliminates air turbulences and a possible resulting particle contamination. In addition, no damage or micro-scratches can occur on the substrate.

Our technology is suitable for clean rooms as well as for environments with higher temperatures. To hold a wafer from above without contact, a combination of vacuum and ultrasound is used.

Our technology is suitable for clean rooms as well as for environments with higher temperatures. To hold a wafer from above without contact, a combination of vacuum and ultrasound is used.

The chuck enables inspection, alignment and centering of the substrate and can also be used for marking and reading operations. It is used for the handling of (coated) wafers or glass as well as other applications.

Features of the UltraLevi-Chuck:

- No surface contact

- Neither damage nor contamination

- No necessary use of compressed air

- High flatness of the substrate

- Lower energy consumption

- Clean room compatible