Wafers & Chips

Wafers are fragile and thin, so gentle handling of these substrates is required in all process sequences to avoid fragmentation or damage.

Our ultrasonic technology generates repulsive forces between the surface of the sonotrode and the wafer. This allows the wafer to be handled gently and smoothly.

The ultrasonic air bearing allows separation, gripping and transport without touching the workpiece.

Advantages:- Significantly shorter cycle times compared to conventional processes

- No micro-scratches, no chipping, no damage

- Double-sided inspection of the wafers possible

Glass

The production of glass is a complex process. Substrates are becoming thinner and thinner, so new methods for innovative handling solutions are needed. Fragile and flexible substrates break easily or can be deformed.

Our handling systems use an ultrasonic air bearing, which avoids mechanical contact with the substrate. The air bearing creates a film on which the substrate floats. This technology has a high heat tolerance.Advantages:

- No surface contact and therefore no damage

- More freedom in process flow and machine design

- Modular design

- Flatness of the substrate during the transfer process

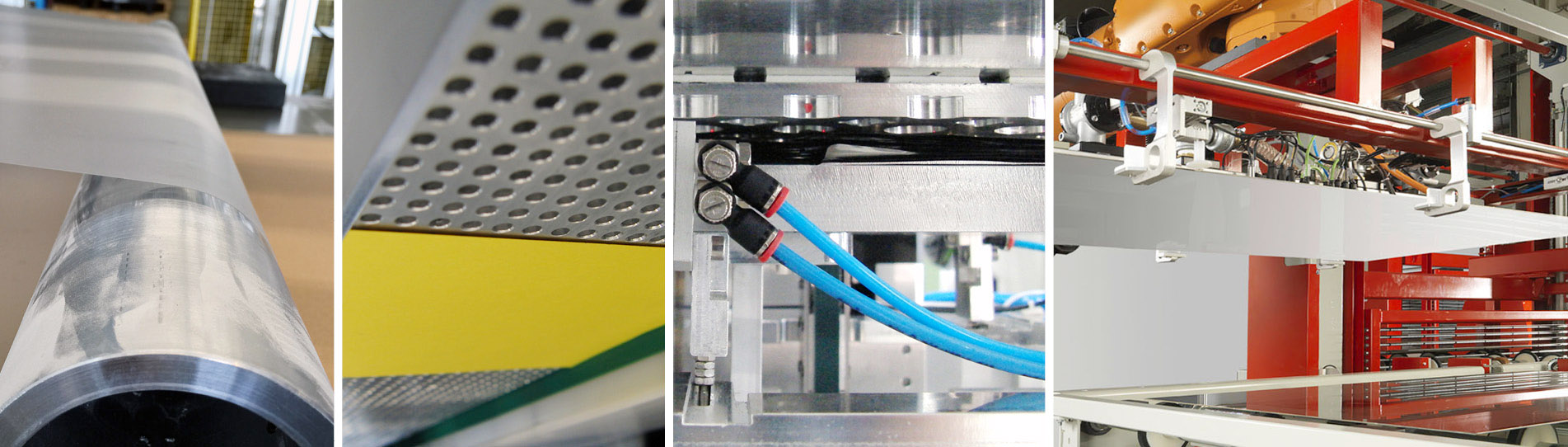

Foil

The sensitive surface procurement of films requires the use of innovative technologies during production and handling.

The patented ultrasonic bearing technology of ZS-Handling offers contactless handling of various types of film without damaging the surface. Application examples are grippers, end-effectors and transfer systems.

Advantages:- No contamination and micro-scratches on the films

- Double-sided inspection of the films possible

- Adjustable web tension for certain systems

Battery and fuel cell

Complex material and surface properties present a challenge in the manufacture of battery cell stacks.

ZS-Handling offers an ultrasonic suspension technology as a solution, which is used in grippers, end-effectors and transfer systems. This allows different types of film to be transported without touching the surface. Our grippers are used for the smooth stacking of films and battery cells.

Advantages:- No contamination and damage of the films

- Transfer of cathodes and anodes in one system, without transfer of particles

- Double-sided inspection possible

Lenses

Due to their sensitive surface, optical lenses face high challenges during production in terms of handling.

We use a technology in which the lens is gripped contactless by a combination of ultrasound and vacuum. Both hard and flexible lenses can be handled with this technology.

Advantages:- No micro-scratches and impurities on the lens body

- Suitable for different diopters

- Customizable according to customer specifications

Packaging

Packaging materials have often sensitive surfaces. Gentle handling is therefore required in all process sequences to avoid damage to the material.

Our ultrasonic suspension technology generates repulsive forces between the surface and the material so that the packaging materials can be handled contactless.

The Ultrasonic Air Bearing enables separation, gripping and transport, as well as roll-to-roll applications without touching the material.

Advantages:- No micro-scratches, no contamination

- Adjustable web tension

- Flatness of the surface during the transfer process