Gentle handling with the assistance of ultrasound

There are now many concepts for the gentle handling of workpieces, but they differ essentially in their possible areas of application. Not only in the manufacture of medical products within medical technology such as interocular lenses, but also in the production of wafers the breakage rate of those sensitive workpieces must be minimized, and the cleanroom requirements have to be met. Within the production processes, contamination by airborne impurities must be avoided at all costs to maintain the functionality as well as the quality of the products.

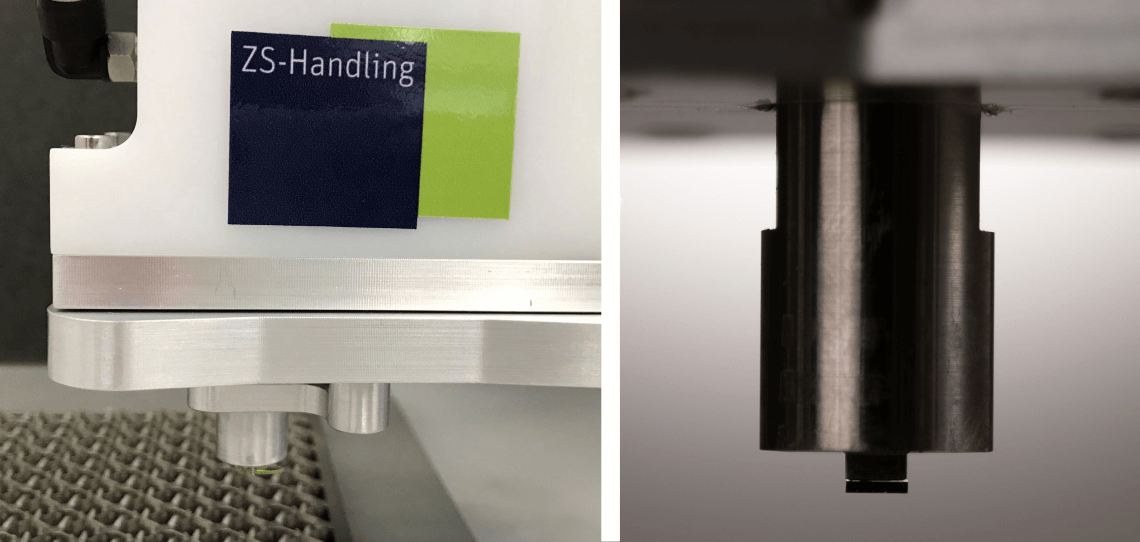

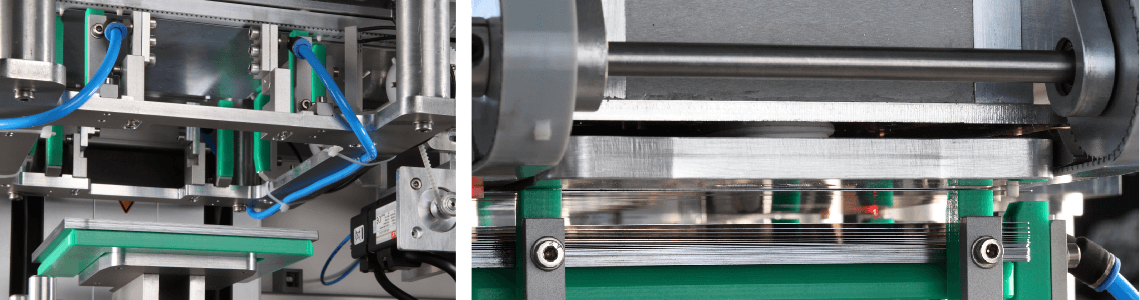

Products of ZS-Handling GmbH in the cleanroom

ZS-Handling GmbH impresses with its patented ultrasonic technology, which enables contactless handling within defined production processes. With the help of ultrasound, a gas film with a distance between 10-150 µm is maintained between the substrate and the ultrasound-generating sonotrode. This means that there is no contact between sonotrode and workpiece, nor is it necessary to use a compressed air supply. The combination of these factors allows the ultrasonic technology in ZS-Handling's products to be used in clean rooms up to classification ISO 1 without any problems. Another advantage of ultrasonic technology regarding cleanroom requirements is that substrates are automatically centered when gripped up without the need for an additional positioning process. If such a process is eliminated, the risk of contamination by possible particles is automatically minimized.

Many handling systems, such as the Bernoulli gripper, have significant problems in terms of complying with cleanroom requirements. The decisive factor here is contamination by particles. The use of so-called air bearings creates air turbulence, which can contaminate sensitive medical products as well as wafers and thus make them unusable. Other handling systems, which do not work with compressed air but with the use of vacuum technology, will leave traces in the form of marks or scratches on the handled workpieces. For work within the cleanroom, such impacts on the substrates within the manufacturing process are not justifiable.

In which industries are cleanroom requirements found?

Meanwhile, cleanroom production is established in many industry segments which means that handling systems inside production fulfilling the requirements for ISO cleanroom classifications are increasingly requested. When thinking of cleanroom requirements, the most common application area seems to be within medical technology. However, this is far from the only industry where cleanroom requirements are needed in production. There is also an increasing demand for handling systems with cleanroom certification in chip and microelectronics manufacturing as well as within the automotive and optics industries.

Our standard products for the cleanroom

In practice, many solutions that ZS-Handling sells to its customers are exclusive and individually customized to the customer's needs. Nevertheless, there are also application examples for our standard products. In wafer production, the LeviWafer gripper is a good example, which can be easily integrated into the wafer production process of customers. ZS-Handling GmbH also offers a standard product to produce lenses in medical technology in form of the OptoMicroMed gripper. The non-contact handling as well as the compatibility with all robot systems are only two of the many reasons why this handling system qualifies for cleanroom requirements.