Contactless wafer handling

Contactless handling in PV industry

Within the last years competition inside the photovoltaic industry became more and more competitive, therefore most producers of solar wafers are forced to increase process efficiency in their handling strategy. When optimizing existing handling systems for solar wafers, the focus is not only on increasing efficiency, but also on reducing process costs substantially. This can only be achieved by using innovative handling technology that can be easily integrated into the existing, overall production process.

A growing industry with increasing needs

Due to strong growth rates within the last few years, the photovoltaic industry has attracted attention and gained importance worldwide. However, international competition also means that producers are exposed to enormous cost pressure and must always be on the lookout for new, more efficient technologies to upgrade production facilities.

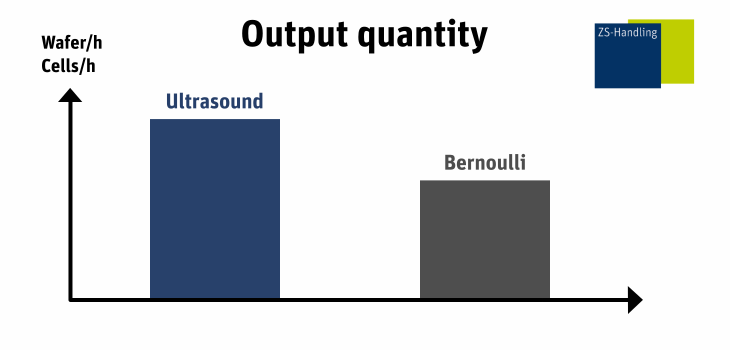

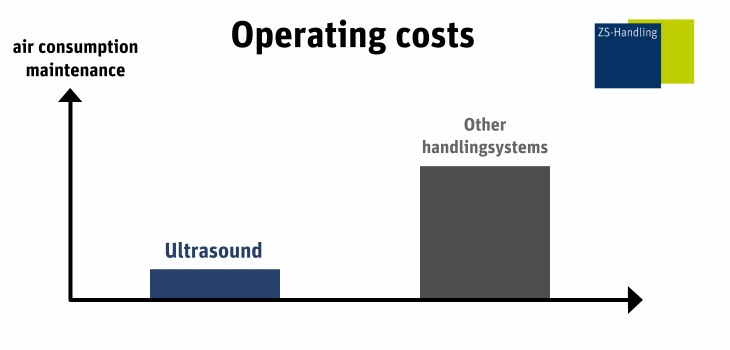

If the very high level of automation and efficiency of existing solar wafer production plants is observed, there are in fact only two main parameters that can be adjusted in order to increase efficiency. On the one hand, this would be the systematic minimization of operating costs, on the other hand, the increase of the output quantity or the reduction of the breakage rate of solar wafers.

The entire handling process of solar wafers is considered to be of central importance. Essentially, the transport, loading and unloading processes for cassette storage must be seamlessly integrated. Thanks to the non-contact ultrasonic technology in the handling systems from ZS-Handling, a contactless linking of the abovementioned processes is possible without any problems.

Non-contact ultrasonic handling in detail

The current state of the art is expressed in the use of so-called Bernoulli or vacuum grippers. Of course, both gripper methods have their justification in solar wafer handling, but in contrast to the previous gripper solutions, ZS-Handling offers a completely non-contact alternative.

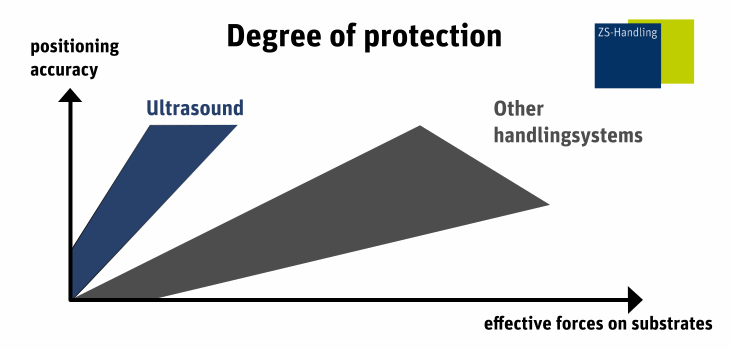

This means that damage to contact-sensitive materials such as ultra-thin solar wafers is virtually eliminated during the handling process. The reason for this is the absence of possible air turbulence due to the use of negative pressure, as is the case with Bernoulli grippers. In addition, contamination of workpieces by particles or similar is avoided due to the lack of contact between the gripper and the solar wafer.

Due to the fact that the solar wafers are handled without contact, the impact of force on the wafers is reduced to a minimum. Microstructure damage, which occurs when using conventional Bernoulli or vacuum grippers, can lead to reduced end product quality or even wafer breakage in downstream process steps.

No contamination

of solar wafers by particles or pollution in the air.

Minimum breakage rate

due to the absence of air turbulence on the workpiece.

Low operating costs

due to reduced power consumption with ultrasonic use.

Higher throughput

possible due to faster throughput times in production.

Further advantages of non-contact handling of ZS handling.

Due to the fact that no negative pressure has to be generated for the handling of solar wafers, operating costs are significantly reduced when using ultrasonic technology. In addition, life cycle costs are expected to be low, as the ultrasonic system itself can be considered almost maintenance-free.

Furthermore, high throughput rates can be achieved using non-contact ultrasonic technology. The solar wafers literally glide on a film of gas, so that only minimal push forces are required along the process line.

It is also essential to mention that a large number of upstream and downstream process steps in wafer handling can take place without contact as well. This includes the entire transport route, unloading, inspection and loading into so-called cassettes.