Contactless foil and packaging handling

Contactless handling of films and packaging

In the handling of films and packaging, it is particularly important not to damage the surfaces of the corresponding substrates. Due to more and more sophisticated films as well as packaging of products, more and more intelligent handling systems are required, which not only work with a very low error rate, but can also guarantee a high production speed. The non-contact ultrasonic technology of ZS-Handling is optimally applicable for the handling of foils and packaging.

The drive for greater effectiveness and efficiency

Due to the increasing demands on modern production in terms of effectiveness and efficiency, the question of proper as well as up-to-date handling systems arises for many companies. This is not only the case for handling small parts such as chips or wafers, but also for films or packaging. It becomes particularly interesting when films or packaging must not be damaged or contaminated during handling. This is often the case with medical products. The same applies to battery foils, which must not be damaged under any circumstances.

In such cases, the non-contact ultrasonic handling of ZS-Handling GmbH can come up with an advantage. The non-contact handling of substrates not only significantly reduces the rate of possible damage, but also eliminates contamination by particles due to the absence of contact points. The patented technology of the ultrasonic bearing enables repulsive forces between the handling surface and the substrate, so that packaging materials as well as films can be guided quickly and without contact along a production line.

The advantages of our products in detail

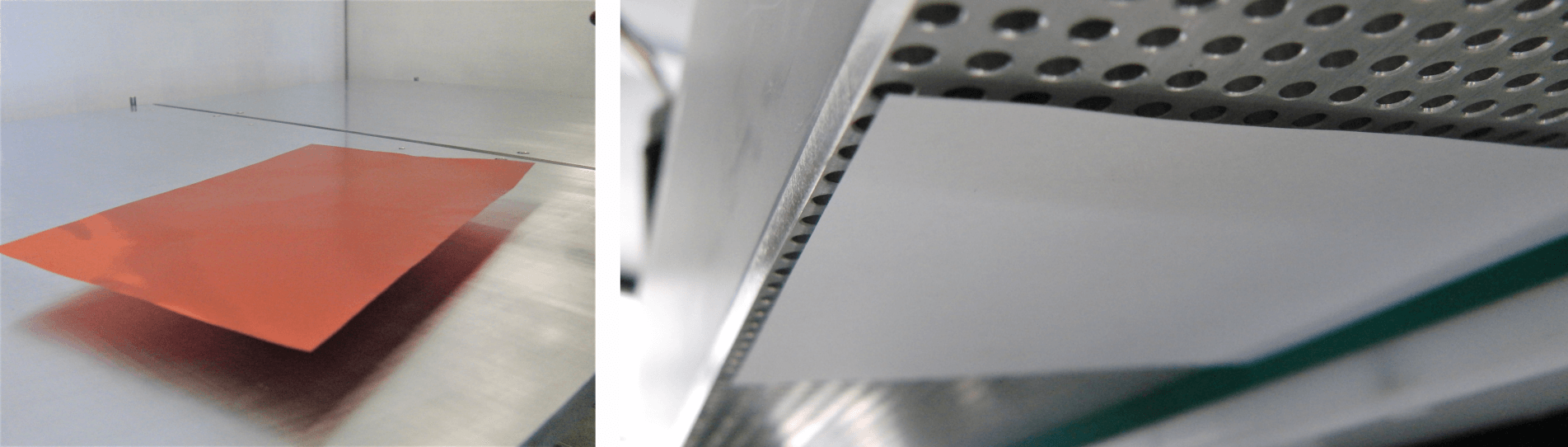

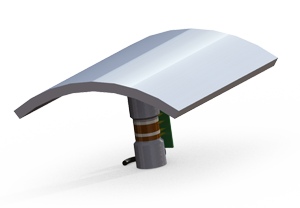

With the help of the LinearLevi-Conveyor, substrates such as battery cells, films as well as other packaging can be conveyed along defined paths. This handling system serves as an ideal link between an upstream and a downstream stage of the process without touching the substrate.If handling of films and packaging from above is relevant for your further process steps, this is possible with the LinearOverhead-Transport. Through the dual use of vacuum and ultrasound, films or packaging are simultaneously attracted and kept at a distance, so that there is no contact with the substrates. However, absolute prevention of contamination can no longer be guaranteed by maintaining negative pressure in this case.

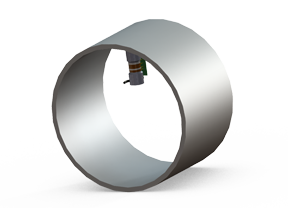

Another possibility for handling films and packaging is the Levi-Roll transport system. This roll-like sonotrode ensures that the substrates are kept at a distance and that there is no contact. Several rolls can be combined so that roll-to-roll transport can take place. It is also interesting to note that it makes no difference whether the packaging is sticky, coated or conventional film. In all cases, there is no contact between the handling system and the material, so that fast and safe transport can be guaranteed.

High process speed

due to non-contact handling along defined paths.

Decreasing costs

due to higher output with reduced contamination rate.

High Flexibilty

due to possible use of negative pressure and handling from above.

Increased precision

through non-contact handling technology for sensitive substrates.

Customized solutions

From experience we know that production processes are different in every company. ZS-Handling GmbH would like to help you optimize your production and fully utilize your capacities. Non-contact ultrasonic handling is the ideal way to do this. Feel free to contact us and we will work with you to create the right strategy for the production facility of the future.

Further information

If you would like to learn more about non-contact ultrasonic handling, you will find the information you need under our Applications tab. Furthermore, the news section offers exciting insights into the technical background of ultrasonic technology in various industrial sectors.