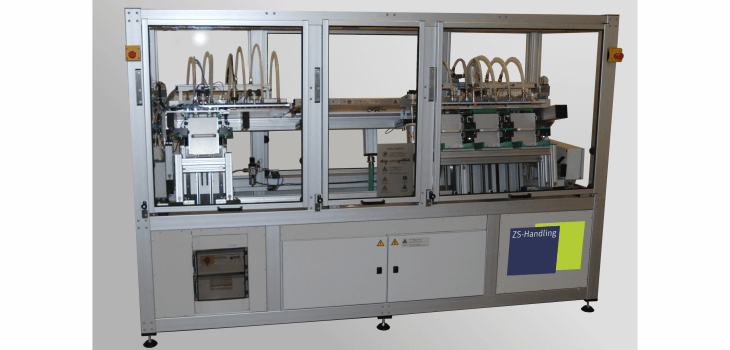

Handling systems from ZS-Handling

Fully automatic, non-contact handling

The handling of various workpieces and substrates is what the term handling is all about. In the context of an increasing degree of automation within production facilities, there is more and more talk about fully automated handling systems, which offer not only cost but also time advantages compared to manual handling. With its non-contact ultrasonic handling, ZS-Handling GmbH offers a solution that is particularly aimed at production facilities where contact-sensitive workpieces have to be handled.

An investment for the future

Investing in a fully automatic handling system is initially deterrent for many companies since high costs are set against a supposedly constant benefit. However, this is not correct in this portrayal and needs to be corrected. The introduction of a non-contact handling system significantly reduces running costs, since personnel costs can be saved, for example. Furthermore, the efficiency of production plants increases considerably, as higher throughput times and lower error rates can be achieved by fully automated handling.With its patented ultrasonic technology, ZS-Handling GmbH is the leading supplier of non-contact handling systems using ultrasound. For many application areas there are already standardized handling solutions, which can optimize various processes along a production line.

Not only the process of non-contact gripping of workpieces is possible, but also the upstream and downstream processes can be realized with the help of ultrasonic technology from ZS-Handling. This refers to processes such as transporting, lifting, inspecting or packaging substrates. However, ZS-Handling GmbH not only offers standardized handling solutions, but also finds the key for customer-specific challenges.

The advantages at a glance

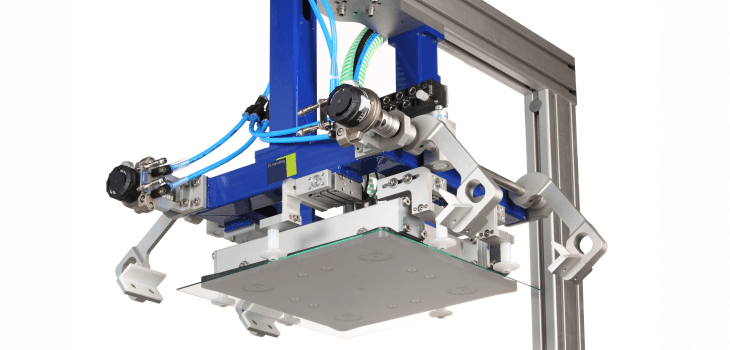

When deciding on automated handling systems, the focus lies often on increasing productivity as well as reducing costs. Because ZS-Handling uses the patented ultrasonic technology for its handling solutions, the running costs are reduced considerably. This is enhanced by the absence of energy-consuming vacuum pumps for maintaining the vacuum which are standard in other handling systems. The increase in productivity is reflected in the maximization of output. High process speeds can be achieved by levitation of the substrate along defined paths.In addition, automated handling systems offer a certain kind of flexibility. By exchanging gripper tips, for example, different handling processes can be realized with a single sonotrode. Flexibility is also offered by the handling systems from ZS-Handling, among other things, by the fact that the systems for non-contact gripping can be connected to all common robot systems. This creates enormous freedom in the prior composition or modification of fully automated handling.

High process speed

with increasing quality of the end products due to non-contact handling technology.

Decreasing costs

due to minimized personnel expenses and absence of a vacuum generator.

High flexibility

due to possible exchange of the gripper tips on the sonotrode of our handling system.

Increased precision

in manufacturing through non-contact handling technology for sensitive substrates.

Suitable for contact-sensitive substrates

There is a wide range of handling systems which are suitable for different industries in different ways. ZS-Handling's non-contact handling technology is particularly suitable for unstable as well as contact-sensitive substrates in the wafer and chip industry due to the non-contact handling, but glass handling has also proven to be a suitable application for ultrasonic technology. Due to the possible clean room certifications up to ISO 1, medical technology has also established itself as a possible customer group for contactless handling.

Further information

If you would like to learn more about our handling systems and the technology behind them, you will find the information you need under our Applications tab. Furthermore, the news section offers exciting insights into the technical background of ultrasonic technology in various industrial sectors.