ZS-Handling participated in the research project Productive 4.0, that consists of a total of 10 work packages (WPs), each with individual technical objectives. We were part of WP 8, which dealt with smart, adaptive, and intelligent concepts for handling different wafer types (especially thin wafers) and substrates within thin wafer processes. Productive 4.0 was conducted by 109 partners from 19 nations. Infineon, Xenon and HOST are some of the members ZS-Handling has worked with.

The approach consisted of developing and implementing a new concept for online detection of the substrate behavior and an automation concept for automatic handling adaption.

The aims of this project were the realization of an automation framework and the integration of smart handling for critical materials. Also, the demonstrator equipment should save handling procedures and enabling a more stable production.

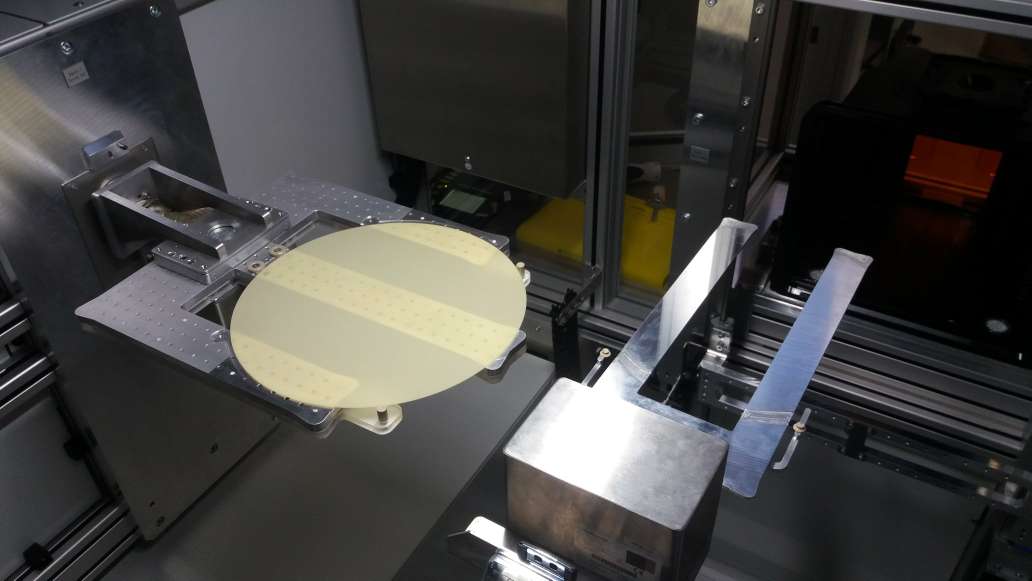

With the use of ultrasonic gripping technology, automated loading and unloading of wafers by using two load ports is possible. Our technology enables standard gripping, top-side gripping and wafer flipping. Furthermore, a camera-based wafer edge recognition tool has been integrated to detect the real wafer position and the wafer bow. This information helps to avoid collisions of the gripper and the wafer during the unloading process. Improved process times, reduced wafer damages, as well as personnel and cost savings are the main benefits of the contact-free wafer handling.

During the project, several F2F workshops among stakeholders supported the work to achieve the project goals. The whole research process was characterized by highly motivated members, a good team spirit and open-minded researchers.