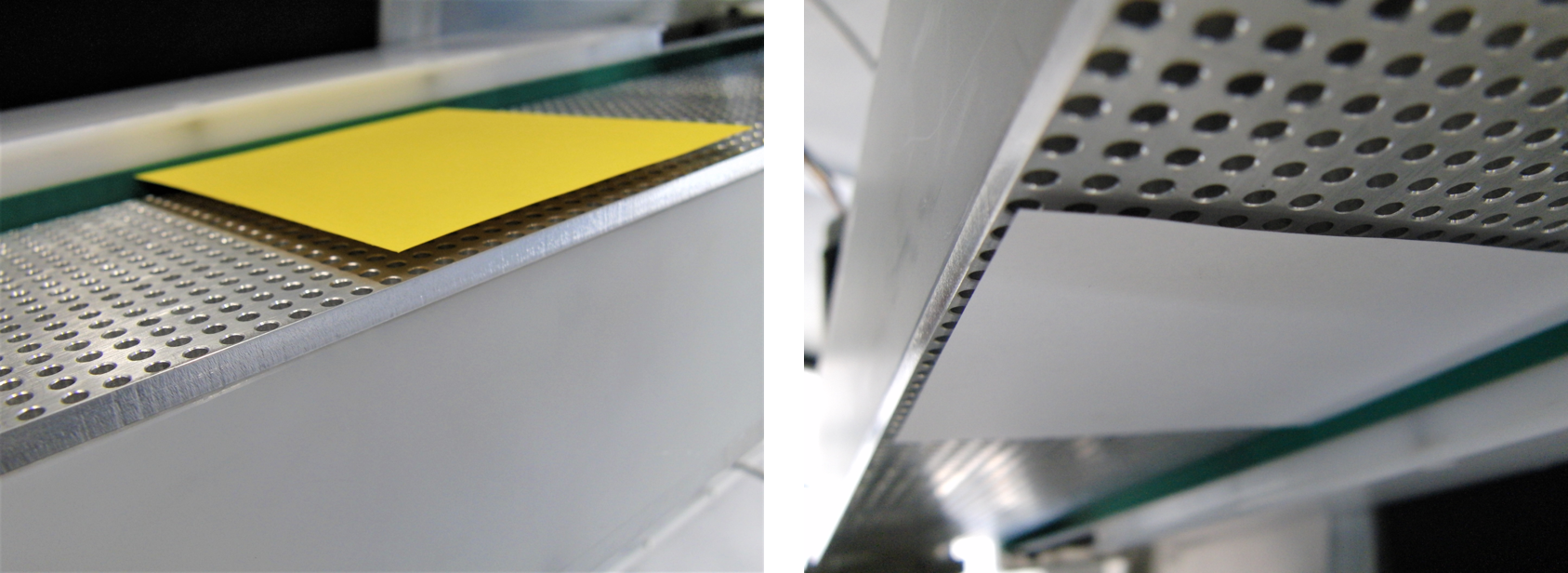

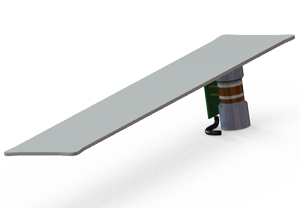

Our handling systems use the non-contact ultrasonic bearing to pick and transport sensitive workpieces particularly gently. They can be used in all atmospheric processes and are also suitable for clean room applications.

Call to action title

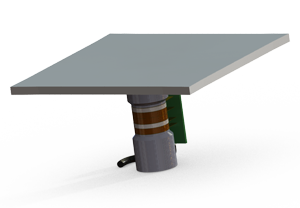

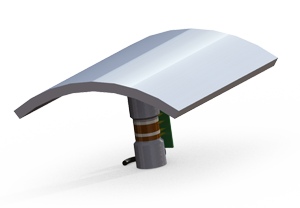

Using a vibration generator with separate power electronics, a compressed air film with repulsive forces is generated. In combination with attractive forces, e.g. with negative pressure, handling without contact is also possible from above.

Call to action title

Innovative Technology:

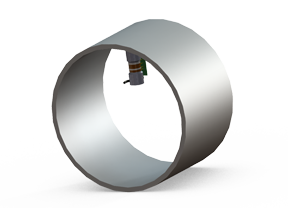

Ultrasonic Suspension Technology

The surrounding air or process gas is compressed by the ultrasound. This allows components to be lifted and guided along defined paths without contact. In combination with negative pressure, workpieces can also be gripped on the upper side - without touching them.

The ultrasonic suspension technology requires less energy than other non-contact handling technologies, such as bernoulli-systems (air bearing).

News & Updates

Summary SEMICON Europa 2023

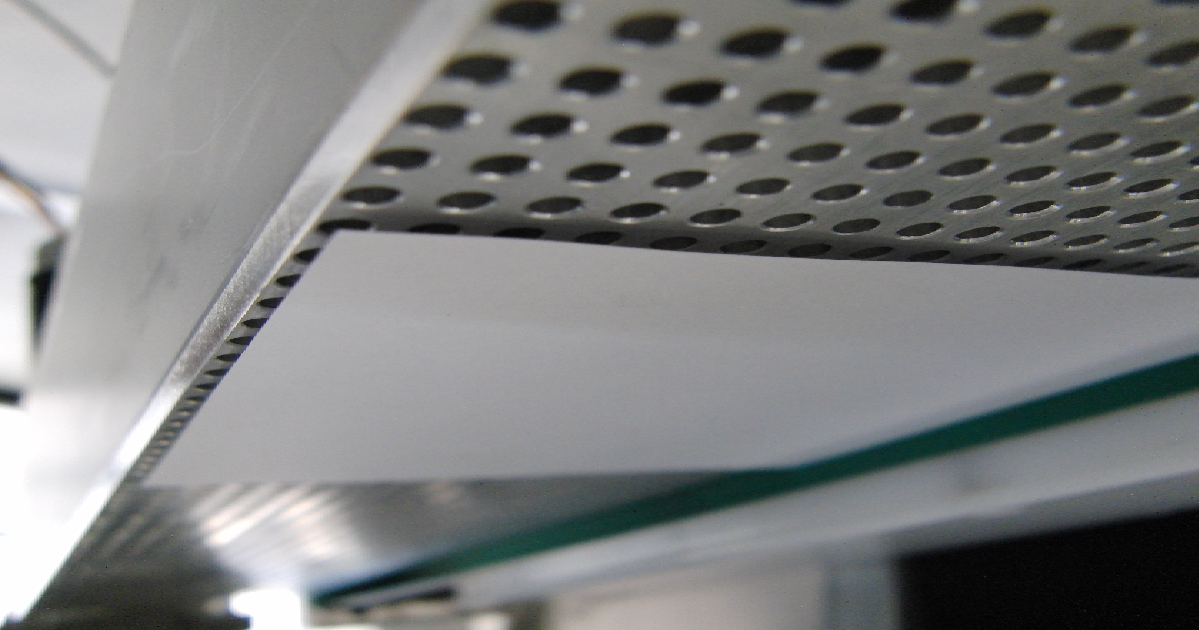

Foil Handling

Summary SEMICON 2021 Europe

The Advantages of Our Technology

- Contactless handling on processed or coated surfaces is also possible from the topside.

- No carry-over of impurities and no air turbulences -> significantly reduced risk of contamination.

- No compressed air generation with complex and cost-intensive air conditioning required -> reduced energy consumption.

- No introduction of mechanical stresses into workpieces -> no micro-scratches, no micro-cracks or other workpiece damages.

- High flatness, also on form unstable substrates.

- High positioning accuracy.

- Easy cleaning and practically maintenance-free -> readout and correction of operating parameters possible during operation.

- Suitable for automation solutions and high throughputs.

- Can be operated both in air and in any ambient gas, e.g. inert gas.

- Suitable for clean rooms (up to cleanroom class ISO 1).

- Low life cycle costs (Total-Costs-of-Ownership [TCO]).

- Double-sided inspection of substrates possible.

Frequently asked questions

However, from experience we know that most of our products need to be customized. Please contact our sales team at any time, who will be happy to provide you with advice and support.